In scientific research, industrial production and People's Daily life, it is often necessary to put forward technical requirements for the air temperature, humidity, cleanliness and airflow speed in a specific space, and take certain technical means to manufacture and maintain the air environment of this space to meet the requirements of research and development, production process and human comfort. This is commonly referred to as air conditioning. For some industrial production workshops, such as semiconductors, microelectronics industry, food, pharmaceuticals, health and other fields, not only have certain technical requirements for the air temperature, humidity, and airflow speed of their environment, but more importantly, there are strict and special requirements for air cleanliness (that is, the concentration of dust in the air in the production environment). To achieve this purpose, the technical measures taken are called air cleaning technology (commonly known as clean technology or purification technology). Therefore, the task of air cleaning technology is to remove the dust-containing suspended particles in the controlled ambient air medium under the premise of meeting the requirements of indoor ambient air temperature and humidity, and make it meet the environmental conditions required for production, that is, we often say air purification. For the room (or limited space) that uses air cleaning technology to control the concentration of suspended particulates and bacteria in the air to meet certain requirements, it is called a clean room.

At present, the application of air cleaning technology can be divided into two aspects: ① industrial cleaning. The air cleaning process for the purpose of industrial production process, its control object is the dust particles in the air, such as dust. For this type of room, the main purpose is to control the dust particles in the air, usually called industrial clean room. ② Biological cleanliness. For the purpose of health care and hygiene, the air cleaning process is controlled by bacteria, viruses and other particles in the air. For this kind of room, because of the bactericidal treatment, and the main purpose is to prevent microbial contamination, it is usually called a biological clean room. The wide application of clean technology in the world has experienced more than half a century of development, from the military industry to the electronics industry, and gradually developed to other industries, its application scope is more and more extensive, technical requirements are becoming higher and higher, the application field has involved military, electronics, food, medicine, health, biological experiments and other aspects.

Grass clean environment online expert system products are divided into two versions according to different application needs: XC-CO-CE-2201-Z401 (for industrial production clean environment), XC-CO-CE-2201-Z402 (for biological experiment clean environment). This article is only for the research and development of edible and medicinal bacteria and factory production: natural cooling (referred to as self-cooling, also known as pre-cooling), forced cooling (referred to as strong cooling), waiting to be connected, inoculation environment; Food and medicinal fungi food primary processing, deep processing, fermentation, brewing, processing, potting, packaging environment; Research and development, storage, breeding and fermentation environment of edible and medicinal bacteria are carried out in terms of environmental assessment and accurate and practical data, and a brief description is given (please contact us separately for details of other clean environment applications).

小草洁净环境专家系统

I. Six kinds of particles and cleanliness evaluation

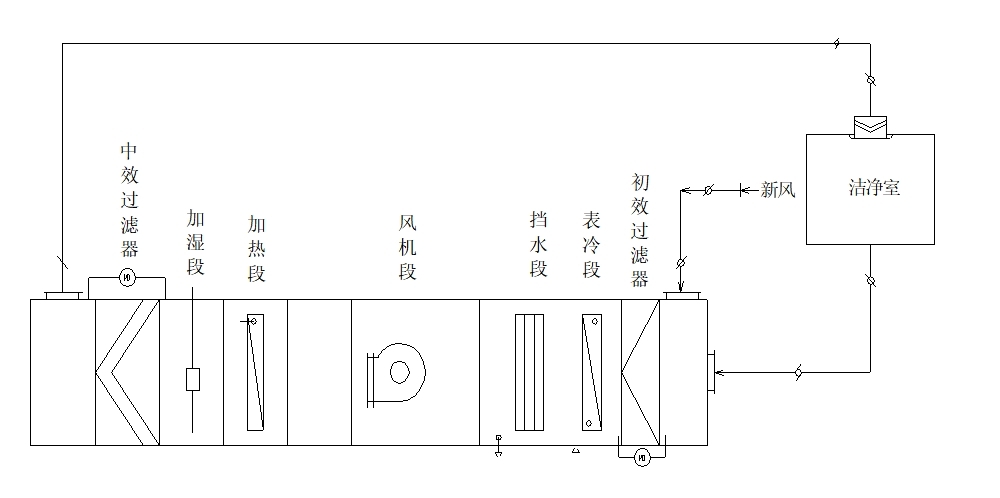

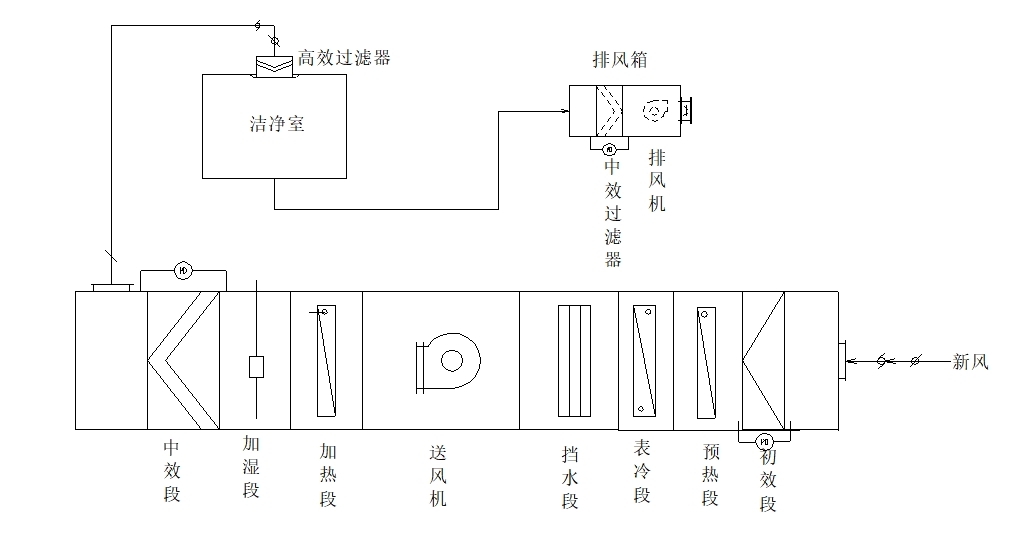

In the air purification system, it is generally used by the primary effect filter, medium effect filter, high efficiency filter (or sub-high efficiency filter) composed of three filtration methods. The role of filters at all levels is: coarse (primary) effect filter: mainly used to filter dust particles above 5μm; Medium effect filter: mainly used to filter dust particles above 1-5um; High efficiency filter (sub-high efficiency filter) : mainly used to capture particles of dust below 0.5um and a variety of suspended matter, high filtration efficiency, low resistance, large dust capacity.

With the development of production technology, the cleanliness of the production environment is required to be higher, and the suspended dust particles in the air medium of the controlled environment are filtered out by purifying the air system, and the artificial inspection method is adopted, with a long cycle and fewer measurement points. Relative to the reproduction cycle of bacteria, it can no longer meet the production needs of modern edible fungus factories for fast operation. The online expert system for grass clean environment is equipped with laser dust sensor for online multi-point monitoring of clean space, which solves the defects of human factors such as long manual sampling time, slow warning and inaccurate cleanliness.

|

|

|

|

小草管道温湿度传感器 |

小草激光粉尘颗粒物传感器

|

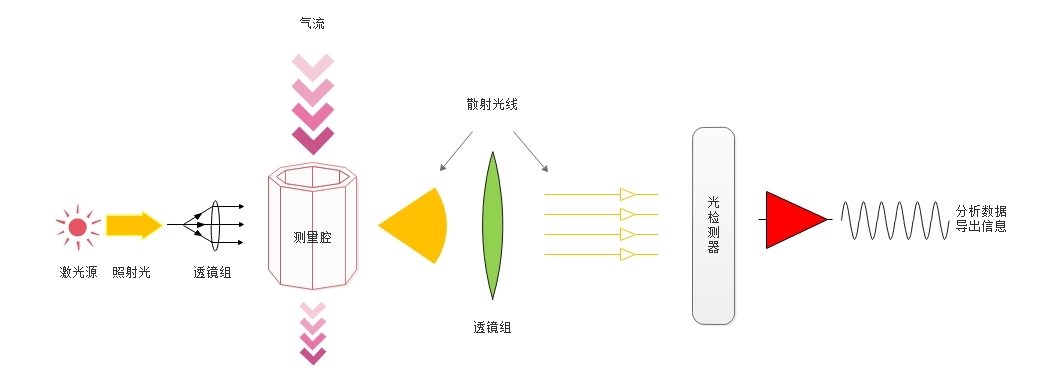

The system conducts dust particle detection through the grass laser dust particle sensor, the principle is as follows:

The on-line particle counter can simultaneously detect different dust particle concentrations of 0.3μm, 0.5μm, 1.0μm, 2.5μm, 5.0μm, 10.0μm in the air. Grass products through the wind speed, air flow cross section, calculation of laminar flow Reynolds number Re=pvd/g data, through the purification of environmental pattern recognition (static mode, dynamic mode) and neural network algorithm online assessment and pre-judgment of environmental change trends, the conclusion of whether it meets the production and processing standards. The comprehensive scheduling and intelligent control of sterilization equipment are carried out by establishing mathematical models in different production and processing environments, and the effect is constantly evaluated in the actual regulation process. The results are evaluated by convolutional neural network algorithm (CNN) and reinforcement learning (RL) : reinforcement learning (reinforcement learning) algorithm continuously optimizes the control model to achieve the goal of accurate, economical and efficient purification and sterilization environment control.

2022-3-1 National Standards Committee issued the "Clean Room and Related Controlled Environment" GB25915-2022 standard: The standard requirements are mainly for the number and area of sampling points in the clean room. The requirements for UCL/LCL calculation of particle concentration are for the standard sampling amount. Each sampling point should be at least 2L, each sampling point should have a small sampling time of 1 minute, and the sampling amount of each sampling point should be consistent. For monitoring instruments (particle counters), calibration is required in accordance with GB/T 29024.4-2017 (equivalent to ISO 21501-4:2007, while the latest version of ISO is ISO 21501-4:2018).

Two, static pressure difference and pressure difference control

In order to prevent the invasion of clean pollutants in most clean workshops, it is necessary to keep the indoor pressure (static pressure) higher than the external pressure (static pressure). The maintenance of the pressure difference should generally comply with the following principles: , the pressure of clean room space is higher than that of non-clean room space; ", the space pressure with high cleanliness level is higher than the adjacent space pressure with low cleanliness level; The door between the same clean room should be opened to the room with high cleanliness level. The "Clean Workshop Design Code" GB50073-2001 stipulates that the pressure difference between different grades of clean rooms and clean areas and unclean areas should not be less than 5Pa, and the pressure difference between clean areas and outdoor areas should not be less than 10Pa.

Combined with the above factors, the intelligent expert system for grass clean environment can monitor the static pressure difference and negative pressure difference, and the pressure difference between clean and unclean areas in real time. Using artificial intelligence algorithm, considering ventilation requirements comprehensively, the reasonable control of wind speed and air volume measurement not only ensures the ventilation volume meets the standard, but also ensures that the pressure difference between the clean area and the unclean area meets the standard.

小草静压差传感器

Third, wind speed and air volume and ventilation times

Clean room air volume requirements: in the preparation of China's air cleaning technical measures have been investigated and measured more than 100 domestic clean rooms, many clean rooms are still under dynamic detection, the results show that: 100,000 grade ≥10 times /h, 10,000 ≥20 times /h, 1000 grade ≥50 times /h ventilation can meet the requirements. The United States federal standard (FS2O9A~B) stipulates that non-unidirectional flow clean room (100,000 class, 10,000 class), room height 8~l2ft(2.44~3.66m), usually consider the whole room at least once every 3 minutes (that is, 20 times /h).

Air volume calculation: Air volume of the air supply outlet (m3/h) = average wind speed (m/s) x air supply area of the air outlet (m2) x3600 Calculation of the number of air changes: The calculation of the number of air changes is calculated by dividing the total amount of delivery per hour by the space volume of the room. Calculation formula: the number of air changes (times /h) = the air volume of each air supply outlet and (m3/h) /[room area (m2) x height]; When testing the wind speed or air volume, if the test result is lower than the standard requirements, the cause must be found and rectified; After the rectification is completed, an application for quality inspection shall be submitted to the QA of the Quality Department. After the inspection is qualified, it can be put into production and use.

Number of air exchange: "Clean workshop Design Code" GB50073-2001 provisions: 1000:50~60 times /h; Class 15~25 times /h; Class 100,000:10 to 15 times

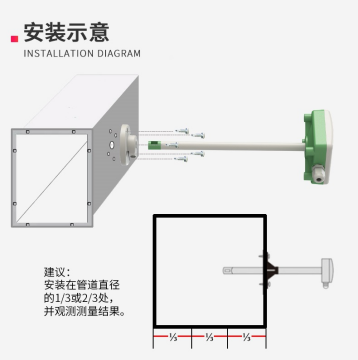

The wind speed and air volume sensor of the grass pipe can effectively determine whether the wind speed and air volume of each tuyere meet the design requirements, including: 1. Provide data support for the clean room air volume platform to maintain the positive (negative) pressure of the clean room, so as to avoid the unorganized penetration of particle pollutants between different levels of clean areas. 2, the FFU fan speed timing control, in non-working hours, automatically reduce the fan speed to maintain indoor clean requirements, to achieve the purpose of energy saving. 3, adjust FFU air volume to maintain a clean environment static pressure difference. Remote monitoring can be achieved through the network; 4, under the premise of meeting the cleanliness requirements, the wind speed can be set according to the actual situation, to minimize the energy consumption of the fan, and to replace the consumables required for the ventilation pipe filtration.

小草管道风速风量传感器

Fourth, ozone concentration and sterilization

Modern industrial clean room air disinfection methods, mainly ultraviolet disinfection, air filtration, ozone and fumigation disinfection and electrostatic adsorption, often in the design of clean workshop will use one or two to control the microbial content in the clean space. Ozone disinfection is one of the main methods, which is universal to most clean workshops. Ozone sterilization is greatly affected by the effect of temperature, humidity and concentration, and usually the ozone sterilization effect is better in the environment of low temperature and high humidity.

Ozone concentration measurement and value: according to the "disinfection technical specifications" and practical application experience, N=5mg/m3 for 300,000; For class 100,000, N=10mg/m3; N=30mg/m3; N=40mg/m3 (1PPM = 2.14mg/m3).

The relationship between ozone sterilization and humidity: ozone decomposes after 15 to 20 minutes at room temperature, and ozone decomposes almost instantly at 200 degrees Celsius, so the lower the temperature of ozone disinfection, the better. In addition, the higher the humidity of ozone in the environment, the better the disinfection effect. Some papers show that under the conditions of room temperature 25℃ and relative humidity of 40% and 70%, the sterilization rate of Candida albicans was increased from 86.0% to 99.93% when the machine was turned on for 2h. When the relative humidity was 40%, the antigenicity of HBsAg could not be destroyed after 6h disinfection. When the relative humidity is increased to 70%, the antigenicity of HBsAg can be completely destroyed. When the temperature is low and the humidity is high, the killing effect is good, especially the humidity, the relative humidity is less than 45%, and ozone has almost no killing effect on suspended microorganisms in the air. It gradually increases at 60% and reaches its maximum at 95%.

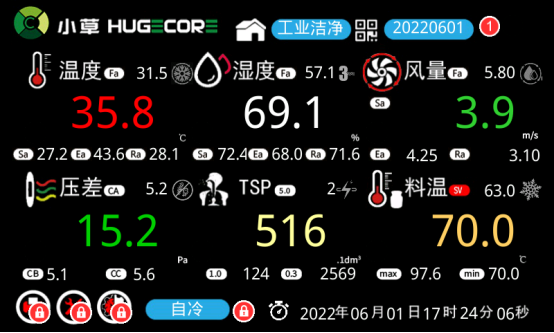

小草洁净环境专家系统监测界面图

小草洁净环境专家系统控制界面图

The intelligent expert system of grass clean environment can monitor ozone concentration, humidity, ultraviolet radiation intensity, etc., and alarm to remind personnel to evacuate when sterilization is opened to ensure that sterilization requirements are met and staff safety is ensured. Historical data of ozone concentration are also preserved.

5, static environment, dynamic environment detection and self-cleaning time

Through the continuous detection of static and dynamic environments and the analysis and calculation of self-cleaning time, the system analyzes the self-cleaning capacity of the clean room by artificial intelligence, and plans the production and operation time, operation intensity and frequency according to the self-cleaning capacity curve, as well as shifts, materials, personnel, etc.

Self-purification test: 1, self-purification test is to determine the ability of the facility to remove airborne particles. 2, the self-cleaning performance is related to the proportion of circulating air in the controlled area, the geometric position of supply air and outlet air, thermal conditions and air distribution characteristics. In unidirectional flow system, the pollution is replaced by controlled air flow, and the self-cleaning time is affected by location and distance. 3, the self-cleaning test should be carried out when the facility is empty or static.

Self-purification evaluation :1, with 100:1 self-purification time for evaluation, the particle concentration to reduce to 0.01 times the initial concentration required time. 2. Using the recovery rate assessment, the self-cleaning time is determined using the curve rate at which the particle concentration decays towards the desired cleanliness.

Self-purification requirements: After the completion of all production operations, the operator is evacuated from the site and after 15min to 20min (guidance value) self-purification, the suspended particles in the clean area should meet the new GMP clean room "static" environmental standard. For Class B area, the design should be in accordance with ISO6 level, and the number of air changes should be 60 /h~65 /h (recommended value) to meet the self-purification requirements. For Class C zone and Class D zone, the number of continued air changes should also be considered with an appropriate margin.

6. Material temperature and production standard

Culture material temperature, culture material moisture content, culture material pH value is very important for the rapid germination of bacteria (see the product introduction of grass culture material expert system), after humid heat sterilization, culture material will enter the clean environment process, most of which can be subdivided into self-cooling stage, strong cold stage, to be received stage, inoculation stage four processes. The precise control of culture temperature in different production stages can form a production standard with independent property rights, which plays an important role in improving yield, accelerating strain germination rate, shortening production time, and accelerating spatial circulation rate.

Self-cooling stage: 1. Monitor whether the self-cooling environment meets the clean standards of the self-cooling chamber; 2. Accurately collect the change of material temperature in the self-cooling stage, and comprehensively evaluate the relationship between natural cooling time, environmental infection rate and production efficiency; 3, the formation of self-cooling stage material temperature enterprise production standards, namely: "to meet the standard, green light, into the strong cold".

Strong cooling stage: 1, monitoring whether the strong cold environment meets the clean standards of the strong cold room; 2. Accurately collect the change of material temperature in the strong cooling stage, and comprehensively evaluate the relationship between the strong cooling time, strong cooling energy consumption, environmental infection rate and spatial production efficiency; 3, the formation of strong cold stage material temperature enterprise production standards, namely: "meet the standard, green light, enter the waiting".

Waiting stage: 1. Monitor whether the waiting environment meets the clean standard of the waiting room; 2. Accurately collect the change of material temperature in the waiting room stage, and comprehensively evaluate the relationship between queuing time, spatial turnover rate, environmental infection rate and inoculation efficiency; 3, the formation of the waiting stage of material in and out of the warehouse enterprise production standards, namely: "to meet the standard, green light, warehousing, immediate inoculation".

Inoculation stage: 1. Monitoring whether the inoculation environment meets the cleanliness standards of the inoculation room; 2. Monitor whether the air outlet of the high efficiency filter meets the requirements of the inoculation environment; 3. Accurately collect the temperature change of inoculating material, and inoculate according to the optimal germination temperature and water content of bacteria; The pH value of the culture material during sampling and inoculation is coded with the bacterial litter chemical parameters (temperature, pressure, turbidity, viscosity, pH, DO, EC, ORP, dissolved carbon dioxide) during inoculation by the inoculation machine (see the intelligent expert system of grass culture for details). To ensure that the strains have the strongest vitality, and the culture material is most in line with the production standards of strains germination bank enterprises. That is: "best standard, completion of inoculation, information coding, transfer to culture".

小草移动终端工厂洁净环境监控界面

小草移动终端生物洁净环境监控界面

|

|

|

|

|

小草培养料温度传感器 |

小草空气温湿度传感器 |

小草培养料水分含量传感器 |

The intelligent expert system of grass clean environment can query and print the curve of historical data, and the data can be uploaded to the server or data center in real time for traceability and research analysis. Grass products can be widely used in bacteria plants, bacteria packaging plants, scientific research institutes, food processing plants, pharmaceutical production, photoelectric industry, precision electronics, liquid crystal, glass, semiconductor, mobile phone and other fields of all levels of clean room.

More information welcome to pay attention to our public number or contact our customer service staff!